Key details

Date

- 6 October 2020

Author

- RCA

Read time

- 2 minutes

Ganit Goldstein, current MA Textiles student, presents a ground-breaking approach to presenting and producing fashion garments. Her collection, called WeAreAble, includes seven outfits made using 3D printing and craft techniques that are presented in a 360 degree Virtual Reality space.

Key details

Date

- 6 October 2020

Author

- RCA

Read time

- 2 minutes

In a move to revolutionise the fashion production of the future, Goldstein was included in an EU Horizon 2020 Re-Fream grant for selected designers who were chosen to design collections that challenge the current fashion industries production methods.

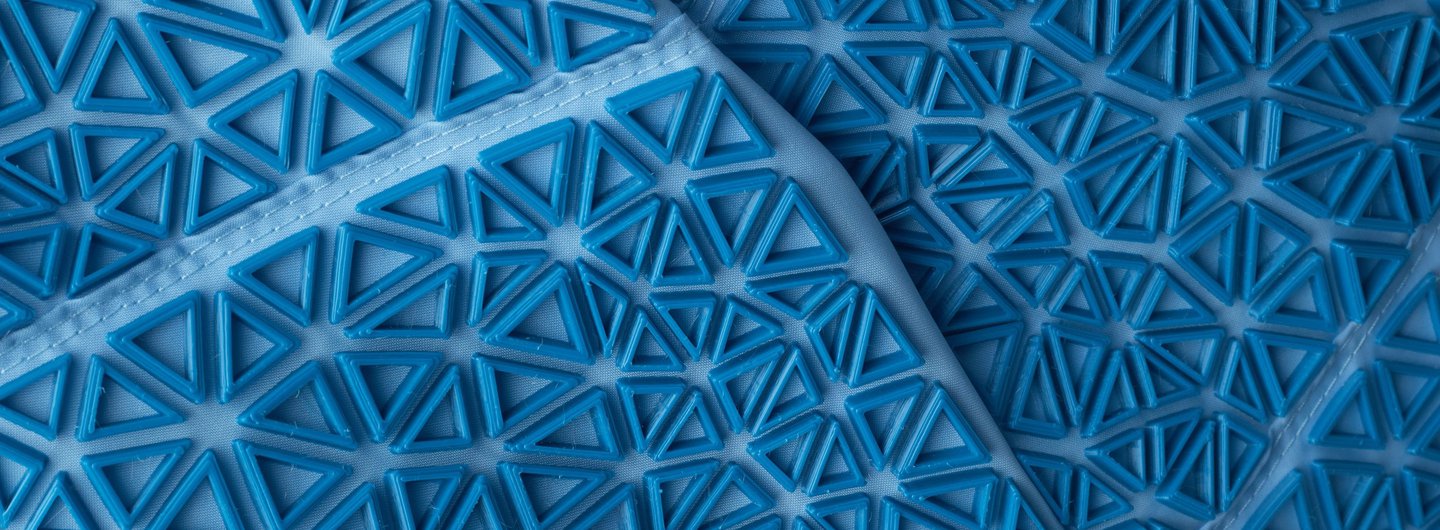

WeAreAble is inspired by traditional Japanese techniques, such as Ikat weaving, and uses a unique combination of hand crafted methods and future technologies. The process of creating the garments is based on measurements taken from a 360 degree body scanner, enabling the designer to create bespoke items perfectly fitting the individual's form. This cutting edge concept of personalised garment production is a move away from the mass production of ‘fast fashion’ technology.

Goldstein uses a body scanner with a ‘depth’ camera to get full body measurements from the individual. Each garment is then crafted from 3D to 2D CAD manipulations which create a single, precise piece of fabric for the garment, meaning there is less need for multiple seams and fabric. The collection focuses on a sustainable approach using 3D printing without any support or waste materials.

‘Looking at the fashion world today, I want to introduce a new way of manufacturing – moving away from mass production to customised design,’ says Goldstein. ‘3D printing has always offered the potential to personalise design in ways not possible before, but to truly create a new way to manufacture requires a new kind of textile. My goal is to create a new hybrid world of crafts and multi-colour 3D printing – connecting past, new and future techniques to evolve fashion design.’

“My goal is to create a new hybrid world of crafts and multi-colour 3D printing – connecting past, new and future techniques to evolve fashion design.”

MA Textiles

‘During the past year, I experimented with numerous different fabrics and technologies to incorporate 3D printing within textiles. Achieving this milestone takes us away from 2D design and opens up a world of wearable 3D garments,’ Goldstein adds.

Goldstein hopes that this cutting edge personalised process will offer an eco-friendly alternative to customers looking to move away from the fast fashion industry. Goldstein comments, ‘The new reality of Covid-19 has pushed me and my partners to think about new possibilities to change the fashion industries current systems.’

‘I was inspired to create the collections using these cutting edge techniques after seeing the devastating impact fast fashion has on the environment. Buying multiple cheaper items not only has an overwhelming effect on the planet it also means lower quality items which the wearer will be unlikely to wear more than once. Making one quality, classic piece which fits the individual perfectly means a more sustainable approach to fashion. I hope that given the technologies we now have available to us, designers will work towards creating fewer, bespoke pieces and we can enjoy fashion without impacting the planet’.

Goldstein showed her collection at a final public presentation at ‘Ars Electronica’ in Linz Austria, Museo Scienza e Tecnologia "Leonardo da Vinci" and Linea Pelle exhibition in Milan, September 2020.